IP69K: Able to withstand hot steam scouring tests defined in EN60529 and DIN40050-9. This can provide protection with water pressure of 100 bar (1450 psi) and temperature of 80 C. Pressure is applied directly to the sensor, progressing at an angle of 30 degrees (0, 30, 60 and 90 degrees), lasting for 30 seconds at each angle for 120 seconds (2 minutes) to prevent water from entering.

These IP protection levels are often not properly understood or applied incorrectly. For example, many users believe that IP67 or IP68 protection levels allow devices to work normally in water within a specified time. This is not the case. These protective levels can only ensure that the equipment can still operate normally after it is removed from the water.

Another possible misconception is that meeting IP69k means automatically meeting IP67 and IP68. In fact, IP69k can only protect against scouring pressure, and is not suitable for submerged water applications. Therefore, IP69k protection level is often used in frequent cleaning and scouring applications, such as breweries, car washers and food and beverage factories, but it is not suitable for applications where equipment is completely immersed in water.

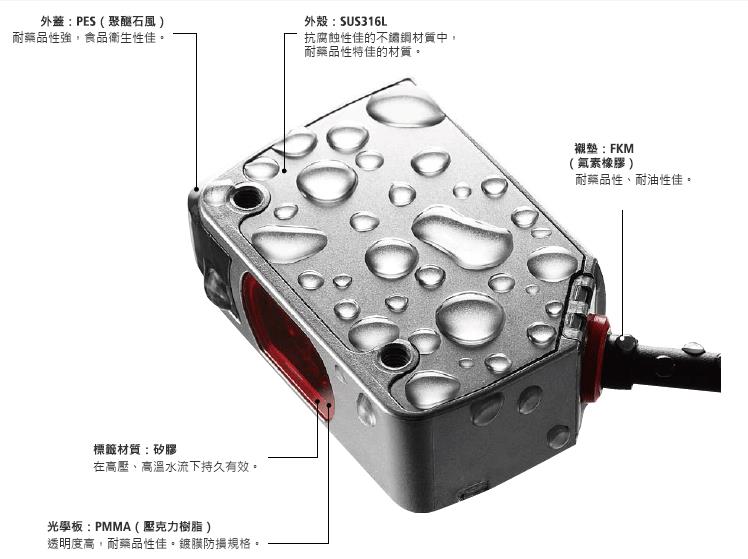

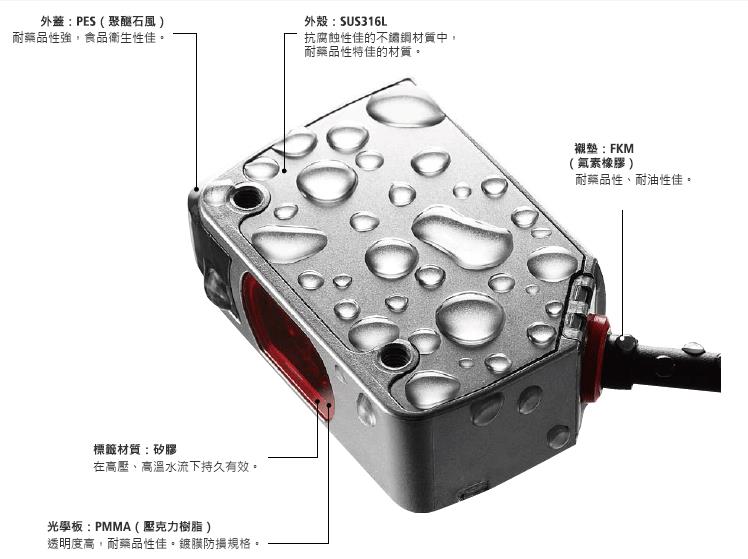

Industrial weighing sensors need to be able to withstand harsh environments, especially in humid environments, to prevent water penetration, especially in environments requiring special cleanliness or use of steam - because IP68 is not enough to withstand high pressure and hot water. The PW15AH single-point weighing sensor released by HBM can provide IP69K. - The highest level of protection can be used in high pressure cleaning environment.

IP69K means:

1. Achieve the highest dust-proof standard (IP6_), and

2. It can reach the highest dust-proof standard and carry out high pressure and steam cleaning (IP_9K).

In order to meet the requirements, the sensors need to be tested according to the "IP69K" standard. The special envoy steps are carried out according to the DIN40050 standard. To ensure objectivity and reliability, the test of HBM's PW15AH weigher is completed by the independent certification authority VDE Prjuf-undZertifierungstut.

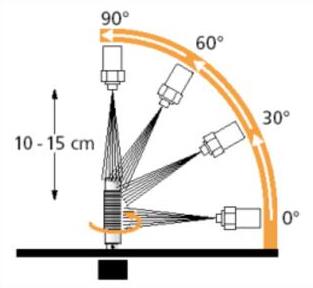

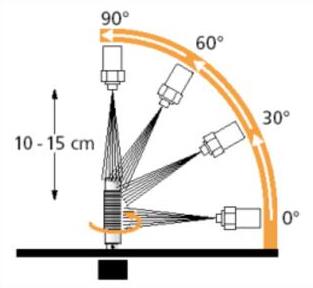

IP69K certification test installation, test samples - such as PW15AH weighing sensor - are installed on the platform. Four ejectors are installed at different positions and angles (0, 30, 60, 90 degrees) for ejection, each for at least 30 seconds. The distance between ejector and sample is 100 to 150 mm - water pressure 100 bars temperature 80 C.

Testing Report from Universal Independent Agency

The M12 series products of ximeconn company have been tested very successfully, and they meet the IP69K protection standard.

The protection level of the sensor is very important - but don't neglect the cable!

Cables are often neglected when sensors are used in harsh environments, but to achieve the highest level of protection, mechanical and chemical changes must be considered to affect cables! Therefore, ximeconn sensors provide effective cable options to meet the requirements. Special connection threads make it easier to connect cable systems. Other companies provide such connection systems. Therefore, ximeconn M12 series connectors are ideal for IP69K protection, even in harsh industrial environments.